Some companies may find it challenging to store products within the warehouse. Storage systems are an excellent option and simple to use. They save time and money in regards to product management. It is necessary to take complete advantage of the warehouse’s space to plan storage solutions that reach the highest levels. A leading storage racks manufacturer in Bangalore has explained the benefits of a multi-tier racking system brilliantly that will help you in making a good decision.

It is important to know that various possible combinations make the storage systems adaptive to the warehouse characteristics. Storage racks are suitable for businesses that do not want to capitalize on new premises, hire extra warehouse space, or undergo the commotion of shifting since these systems are simple to customize according to the available space.

Also Read: The Perpetual Need For Storage Space

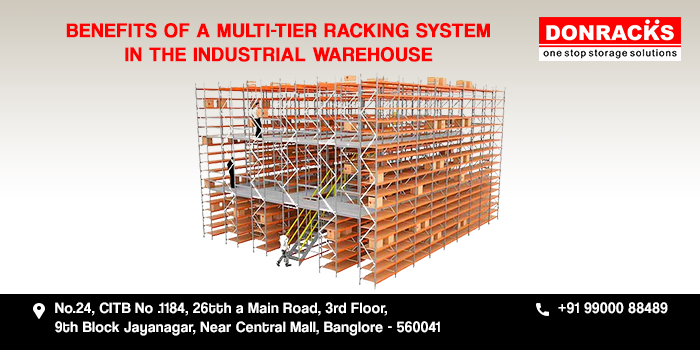

If you want to maximize efficiency and enhance organization, a multi-tier racking system is an excellent addition to the warehouse. It is possible to maximize the cubic area by utilizing these systems. Moreover, it is the best warehousing and storage solution for spaces with high roofs. The racking system can completely change your warehouse functions and remain beneficial in several ways. Let us discuss the benefits of a multi-tier racking system in brief.

8 Interesting Benefits Of Multi-tier Racking System

-

- Space-saving and compact:

Multi-tier racking systems utilize vertical airspace, thereby extending to the ceiling. Due to this feature, you do not have to shift to a new place when you are expanding the business. Extra floor space is obtained and utilized for assembly, packing, and storage requirements. It also permits for maximum floor space utilization, which means most portions of the area will be occupied by the SKUs. - Flexible and modular:

Multi-tier racking systems can accommodate any kind of non-palletized goods. It is suitable for handling different product lines in a single floor area. As it has multi-tier structures, it remains flexible in terms of accessories, options, and the number of levels that can be incorporated. It also vastly enhances the picking adeptness of the warehouse function, thereby making products easily accessible for instant picking.

With multi-tier racking systems, it is possible to manage peak demand after special sales promotions or during the holiday season without any issue. Whenever the demand level increases, the operator’s number can be augmented to help with the increased volume of the orders. Also, there is no requirement to automate the processes. Every area remains easily accessible for immediate order collecting at any time through the incorporation of carton live dynamic shelves or fixed shelves. When required, new shelves can be added or the structure can be reconfigured. - Cost-efficient and operationally effective:

The cost of installing the multi-tier storage system is affordable and also less when compared to the automated storage facility. It is simple to pick products with the same order continuously on several tiers. Most people think that the large steel structure is expensive. But when you compare the expenses with the new facility cost or warehouse expansion, the cost looks reasonable. You have to just invest one-fourth the cost of the automated system to obtain a multi-tier system for the warehouse. Thus, it reduces the financial risk. Its flexibility will assist you to spend very minimally on external and internal logistics. - Customized design:

By investing in a multi-tier racking system, it is possible to customize the model of the storage system. The storage requirements of each company are unique and it does not match with the standard shelving system’s design. With a multi-tier racking system, you can configure in such a way it remains useful for your company. Furthermore, you can completely control the depth and height of each shelf to decrease order fulfilment times and facilitate product retrieval. Whether your installation is designed for 10,000 picks or 100 picks a day, the multi-tier racking system easily caters to your requirements.

- Space-saving and compact:

- Central warehousing:

Several companies opt for a multi-tier racking system to maintain their inventory in a single warehouse. It is challenging to manage several facilities in various locations. With a centralized warehouse, inventory management remains simple, reduces the shipping expenses between warehouses, and excludes utility expenses for different warehouses. - High-density storage:

By utilizing multi-tier catwalks, high-density storage is easily possible. When catwalk levels are added between racks, an increase in the number of access or floor levels throughout the system is accomplished, thus permitting access to the entire shelving levels ergonomically. - Quick installation:

Multi-tier racking systems can be deployed more quickly than the traditional multi-tier storage unit. - Safe and secure warehouse:

If the products topple down from above, there are chances of accidents and the warehouse remains dangerous for the employees to function. A multi-tier racking system reduces such risks and makes the warehouse a safe place. It also does not let employees engage in dangerous storage practices. As the multi-tier racking system comes with additional shelves, entire product stock-keeping units remain easily accessible and at the same time, it can be stored securely and safely on the shelf. When the right multi-tier racking system is selected and installed, it serves as a valuable tool, assisting you in limiting the warehouse accidents that are common in most of the facilities.

Features of multi-tier racking system

Enhancements are possible with multi-tier racking systems. It can be easily calibrated with filing cradles, cupboard doors, plastic drawers, shelf bin fronts, adjustable drawers, and several other attachments. A multi-tier racking system is developed to improve picking operations and is ideal for businesses that maintain a high level of stock-keeping units. It is an excellent solution for the apparel, pharmaceutical, and automobile kinds of industries. It is utilized for picking and storing plastic components, greeting cards, car parts, bookshops, clothing, and more.

To summarize:

The multi-tier racking system is versatile and it is simple to install from scratch quickly. If you wish to enhance the performance and function of the company’s warehouse, it is recommended to add a multi-tier racking system. At Donracks, Bangalore, we design sturdy structures that handle everyday rigidities of warehousing better.