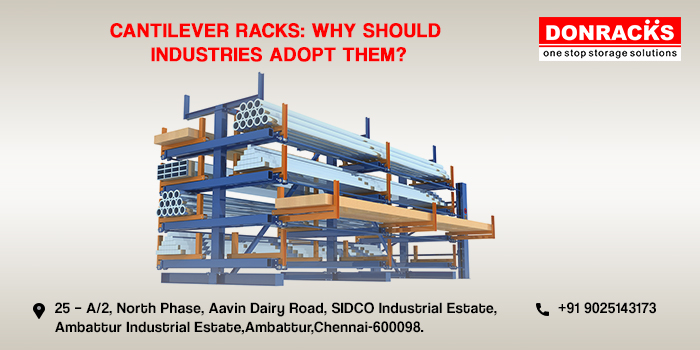

A cantilever racking system is a must-have industrial storage racks solution for various industries not only just in Chennai but also in other parts of India. This storage system exhibits exemplar flexibility in the warehouses. Even though they have exceptional similarity to a conventional pallet racking, the cantilever racking system has a considerable storage capacity than the latter. These racks consist of horizontal beams or arms attached to vertical beams, which are bolted to the base firmly. Typically, a cantilever rack consists of three components: Uprights arm, Arms Brace Sets, and Brace sets.

Upright arms include vertical columns and a horizontal base that is bolted to the column. At least two uprights are essential for forming a storage bay. Arms brace sets are the primary component of a cantilever rack system. Straight arms, hairpin keeper, and inclined arms make up the arms brace set. Brace sets form a horizontal truss system that makes carriage of axial loads in addition to the regular bending and gravity loads much more comfortable.

The modular design of the cantilever racks allows easy expansions according to the size of the storages. The racks are also provided with forklifts to shift loads off the racks easily. The ability of these accessories to retrieve huge loads with ease is quite advantageous.

What makes cantilever industrial storage racks unique?

When material handling industries were putting in efforts to create standard size pallets, different product sizes were making it tiresome to follow a standard storage size pattern. The entire concept of standard pallets was quite conflicting until when cantilever racks were introduced. Cantilever racks are an excellent solution for the products that are unique in size and weight.

Flexibility is what makes cantilever racks distinct from other types of racks as these can be easily configured to meet varying needs. These racks accommodate materials of varying length and, with its unique makeup, can make storage slots readily usable. Varieties of the rack can hold load capacities up to 20,000 lbs per arm. No wonder why the racks are robust enough to hold cumbersome and heavy nonstandard products with fantastic ease. Cantilever racks’ see-through racks make it easier for the workers to locate and fetch the products faster. The easy loading and unloading functionality makes the cantilever system one of the most functional storage racks in the industry.

The ample horizontal space makes the clearance handling easier, also making the area compact enough. The frontal columns can be removed to allow more storage space as well. Unlike the standard pallet system, the handling and storage efficiency has made the cantilever storage racks affordable than other products. Know more about various types of cantilever racks available in Chennai.

Types of cantilever racks

Rugged Cantilever rack storage

Rugged cantilever racks are your standard heavy duty or extra heavy duty that comes with straight or inclined arms of different lengths. These flexible racks vary in heights from 8’ to 20’ and can hold up to 60,000 pounds in their advanced models.

AII- Welded Cantilever rack solutions

All-Welded cantilever racks are utilized for storing tubing, bar stocks, angles, and almost all long and heavy materials with the utmost ease. These affordable racks have a powder-coated finish that makes these structures extremely durable.

Medium Duty/Medium-heavy duty Cantilever rack solutions

Oversized storage requirements heavily rely on these sturdy and robust racks that can withstand years of rough use. Easy installation is another significant feature of these racks.

Galvanized cantilever Rack storage

Recommended for outdoors, freezers, coolers, and other chemical resistant surfaces galvanized racks offer durability and safety as foremost features. The rust-resistant and powder-coated surfaces are sure to increase the racks’ durability features.

Structural or roll-formed cantilever racks

Structural cantilever racks are made of low-gauge steel that is made from hot rolling raw iron. These flexible rack solutions can withstand heavy pallets and harsh conditions, especially in a city like Chennai, with adequate strength.

Standard duty, Light duty, I-beam, and furniture cantilever racks are few other types of cantilever racks. The racks are perfect solutions for storing products such as steel bars, pipes (PVC and metals), Lumbar and drywall, and furniture.

How do cantilever racks optimize warehouse space?

Warehouses are vulnerable to chaos and clutter if products are not organized appropriately. According to the leading industrial rack manufacturers of Chennai, cantilever racks are a popular product in the market because of its fantastic space-saving solutions in the warehouses. These racks can offer storage options for a wide range of materials. Cantilever storage is trendy for its usage in storing massive inventories like lumbar and piping.

Cantilever racks have incredible adaptability for different industries, from furniture to automobiles has resulted in the racks to be known by their purpose they serve. Though the structures might look like an advanced version of the conventional pallet storages, the ability to store comparatively heavier loads and easy fetching of materials makes the cantilever racks a better option than the traditional ones. The ability to hold a wide range of materials also makes these racks a preferable solution for warehouses. Also, the increased holding ability of racks allows ample space freeing up in the warehouses, leaving additional space for handling clearances.